Story

Technology

This is how we FiDU

To grow into committing mistakes was crucial to allow for them. That is how FiDU was born, the metal manufacturing technology that led Oskar Zięta and the Zieta Studio team to the Centre Pompidou in Paris and to MoMA in New York.

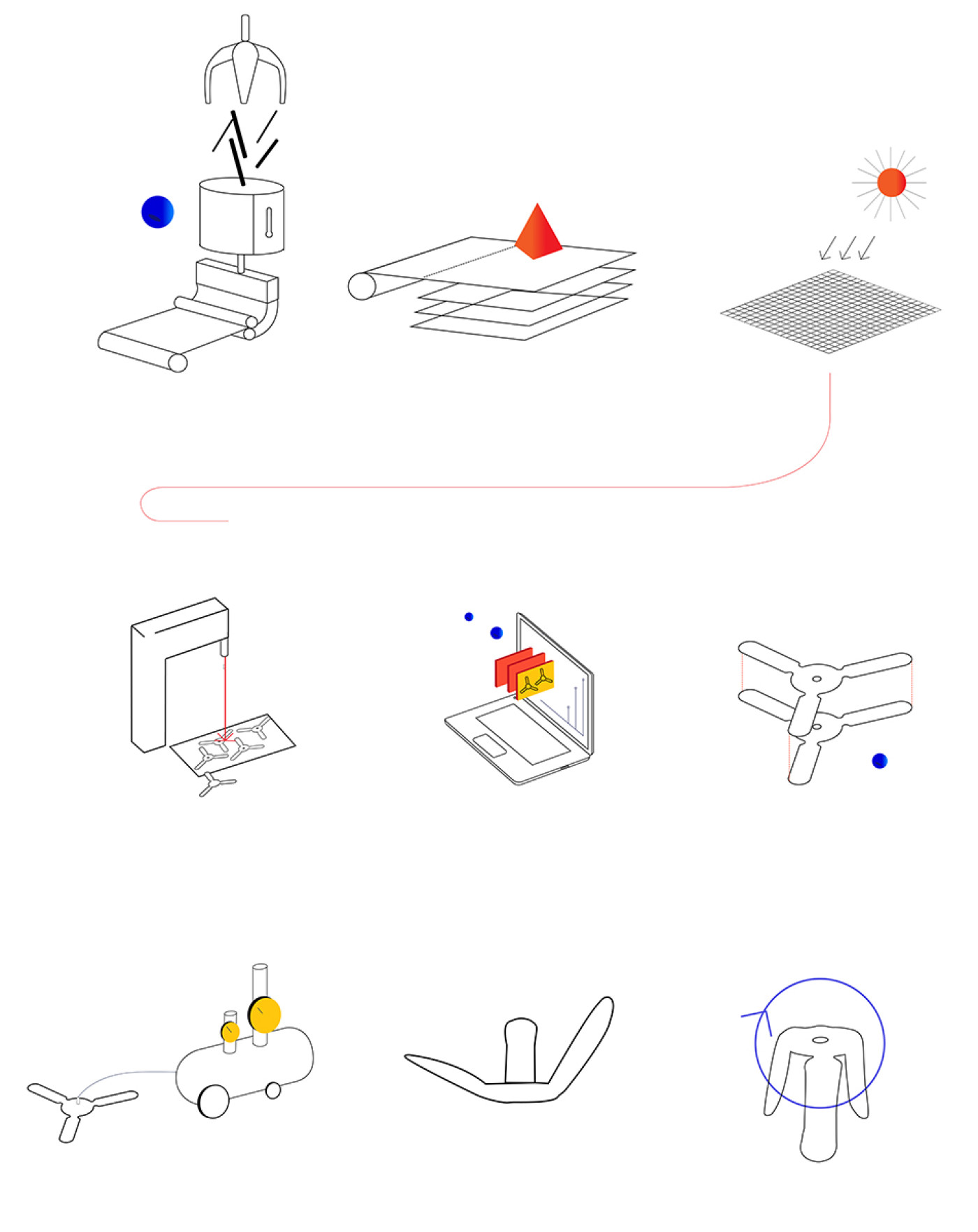

FiDU comes from the German Freie Innendruck Umformung (Free Internal Pressure Deformation). It lets us inflate metal. We laser-cut and weld two or more sheet-metal contours very tightly together. Then we inject high-pressure air, forming the objects from two-dimensional to three-dimensional. We obtain ultra-lightness (objects empty inside), durability (objects made from metal), and functionality (objects ready to use).

FiDU comes from the German Freie Innendruck Umformung (Free Internal Pressure Deformation). It lets us inflate metal. We laser-cut and weld two or more sheet-metal contours very tightly together. Then we inject high-pressure air, forming the objects from two-dimensional to three-dimensional. We obtain ultra-lightness (objects empty inside), durability (objects made from metal), and functionality (objects ready to use).

00:00

00:00

-large.jpg)

-large.jpg)

“Controlled loss of control”

That’s what we call it. We let the material freely reply to the process with its characteristics. We try to predict it, but we never control it. We let internal pressure manifest its irregularities and unrepeatable concaves. We experiment with sizes and shapes. We believe that less weight today means more possibilities.

That’s what we call it. We let the material freely reply to the process with its characteristics. We try to predict it, but we never control it. We let internal pressure manifest its irregularities and unrepeatable concaves. We experiment with sizes and shapes. We believe that less weight today means more possibilities.

As Oskar Zięta says: “FiDU gives us the ability to create forms tailored to specific needs, without expensive tools or moulds. This gives us great opportunities. An example is the Blow & Roll installation made of steel rolled profiles, which can be inflated at any place and transformed from a rolled flat metal ribbon into a durable, lightweight, three-dimensional pillar. Such elements are in demand in any industry, and even useful in the conquest of space. After projects such as Nawa in Wrocław or Wir in Warsaw, I know that FiDU technology has a future in architecture and other branches of industry.”

FiDU origins

Engineers are taught about curved deformations on metal surfaces as an example of a mistake. With his technological fascination and determination, Oskar Zięta took this particular mistake (DIN 8580) and penetrated it, resulting in FiDU.

The adventure started at ETH Zurich, where, before inflating metal, Oskar Zięta used a modification of tube hydroforming, a method used in the automotive industry. Therefore the first PLOPP stool was deformed by high-pressure water injection (3–50 bar) between two metal sheets to force them into a 3D form. Today we use air instead of water.

-large.jpg)

FiDU potential—data and energy savings

The production files required to define the two-dimensional PLOPP’s form are just 16 kilobytes when allowing for its volumetric expansion into the 3D object. Trying to define the same final form for traditional production methods would require 142 gigabytes of data.

FiDU not only saves the amount of material, but also saves massive energy consumption generated by the presence in the virtual world of parametric design. As intangible as it may seem, servers consume horrendous amounts of energy.

We constantly optimize the mix of robotics, new technologies, and human potential. We seek solutions that can improve the accessibility of light, durable and recyclable objects in architecture, design, and future engineering.